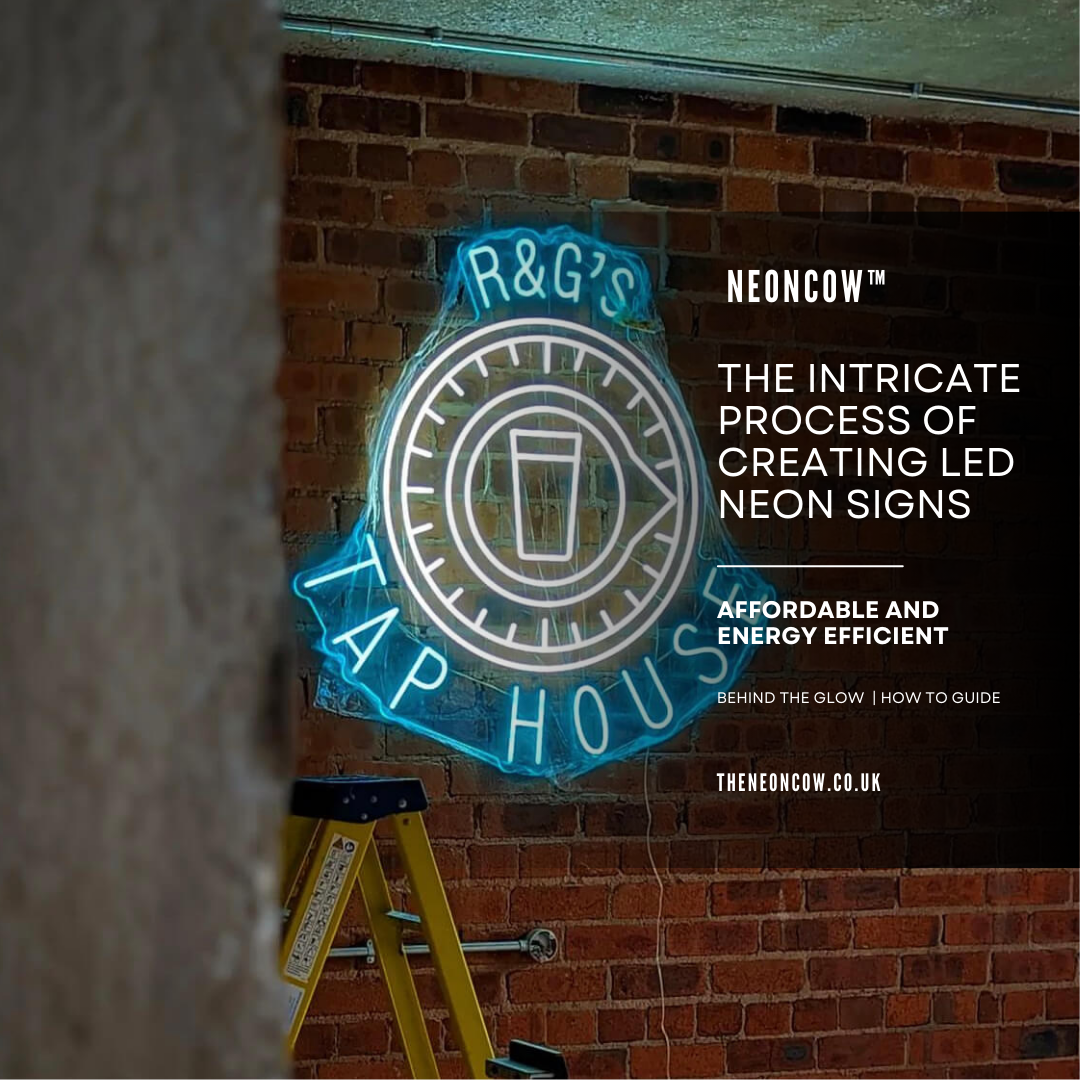

The Intricate Process of Crafting LED Neon Signs

The Intricate Process of Crafting LED Neon Signs

Creating an LED neon sign is an art that combines modern technology with meticulous craftsmanship. Here’s a look at the primary steps involved in bringing these vibrant pieces to life, a process perfected by specialists like those at NeonCow:

-

Design and Planning: Every LED neon sign starts with a detailed design process. Using specialised software, designers at NeonCow transform creative ideas into precise digital blueprints. This step ensures that each curve and element of the sign is perfectly planned to meet customer specifications.

-

Assembly: The core of the sign is made from flexible LED strips, which are carefully shaped to match the digital design. These strips are then mounted onto a durable backboard, typically made of acrylic, which supports the structure of the sign and shapes its contours.

-

Encapsulation and Protection: Once assembled, the LED strips are coated in a silicone layer. This protective coating guards against environmental damage like dust and moisture, and it ensures the light distribution is smooth and uniform, mimicking the classic glow of traditional neon signs.

-

Testing and Quality Assurance: The final step before a sign can leave the workshop is rigorous testing. NeonCow’s team checks each sign for both functionality and aesthetic appeal, confirming that it not only works flawlessly but also lives up to the visual standards their customers expect.